Custom Plastic Moulds

Design and manufacture of custom plastic moulds based on OEM drawings, 3D CAD data, GD&T, and functional requirements, aligned with PPAP documentation and APQP guidelines.

AVA Engineering is a leading plastic injection mould manufacturer supplying custom plastic moulds, OEM-grade plastic components, and prototype injection moulds for automotive and industrial applications across India.

Factory-focused plastic moulding partner for OEM and industrial supply chains

Design and manufacture of custom plastic moulds based on OEM drawings, 3D CAD data, GD&T, and functional requirements, aligned with PPAP documentation and APQP guidelines.

End-to-end plastic injection mould manufacturing from design review, mould flow assessment, and tooling to sampling and production approval for automotive plastic moulds and industrial parts.

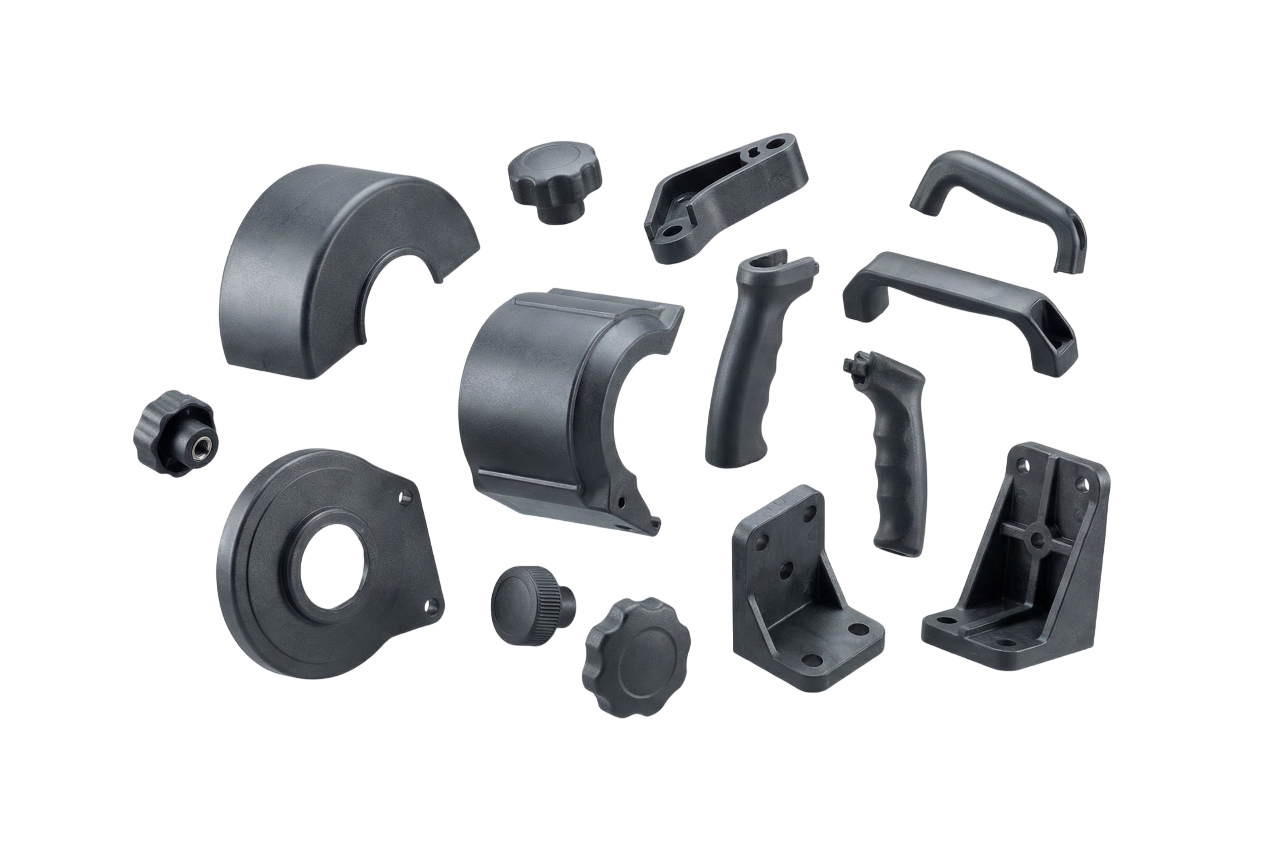

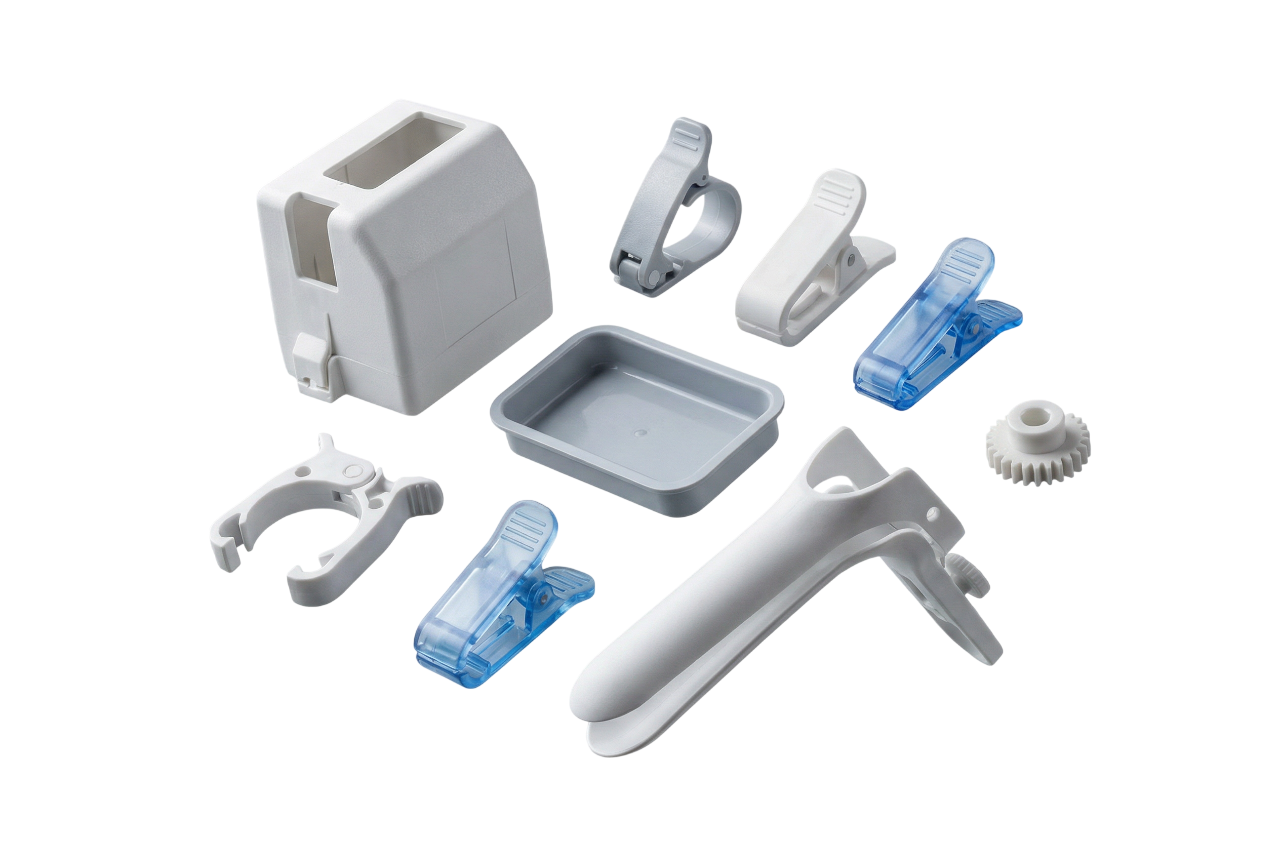

Production of OEM-grade plastic components for interior trims, housings, brackets, clips, and functional assemblies, with process sheets and inspection records for traceability.

prototype injection moulds for low-volume, prototype, and pilot builds where faster turnaround and controlled cost are required before full-scale tooling decisions.

Defined procedures for mould design, tooling, sampling, and production with traceable outputs

CAD-driven design review and mould flow analysis to optimize part quality and production efficiency.

Precision machining and fabrication of mould components using CNC and EDM processes.

High-precision injection moulding with process control and parameter optimization for consistent output.

Dimensional verification and visual inspection based on OEM specifications and control plans.

Secure packaging and logistics coordination for on-time delivery to customer locations across India.

Trusted manufacturing partner across diverse sectors

• Interior trims,

• dashboard components,

• under-hood parts,

• Engine covers (plastic),

• Battery covers,

• Fuse box housings,

• Relay box housings,

• Wire harness clips & holders,

• Cable guides & clamps,

and many more

Enclosures, connectors, switch housings

Machine guards, handles, functional components

Household items, appliance parts, storage solutions

Non-critical device housings and plastic enclosures

Procurement and sourcing teams can share part drawings, annual volumes, and delivery locations for a structured quotation